Understanding the Automatic Embossing Laminating Machine: A Game Changer in the Printing Industry

2024-08-22

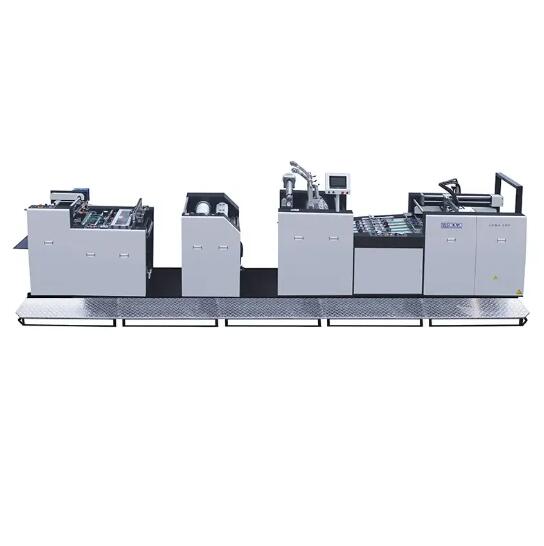

In the printing and packaging industry, efficiency, precision, and high-quality output are paramount. The Automatic Embossing Laminating Machine is a technological marvel that combines these elements to produce stunning and durable printed materials. Whether you're in the business of creating packaging, book covers, or decorative prints, understanding how this machine works can elevate your production process. In this blog, we’ll dive into what an Automatic Embossing Laminating Machine is, how it operates, and why it’s a valuable asset in modern printing.

What is an Automatic Embossing Laminating Machine?

An Automatic Embossing Laminating Machine is a specialized piece of equipment designed to emboss and laminate materials in a single, streamlined process. Embossing involves creating raised or recessed designs on a material, while laminating applies a protective film or layer to the material’s surface. This machine automates both processes, allowing for high-volume production with consistent quality.

Key Features of the Automatic Embossing Laminating Machine

1. Embossing Unit: The machine is equipped with an embossing unit that uses engraved rollers or plates to press patterns into the material. This unit can handle various designs, from simple logos to intricate textures.

2. Laminating Unit: The laminating unit applies a thin layer of film over the embossed material. This film not only enhances the appearance by adding gloss or matte finishes but also protects the material from wear, tear, and environmental damage.

3. Automation and Control: Modern machines come with advanced automation features, including programmable settings, touch-screen interfaces, and sensors. These allow operators to control the speed, pressure, temperature, and timing with precision, ensuring consistent results.

4. High-Speed Operation: Designed for efficiency, these machines can process large volumes of material in a relatively short time, making them ideal for commercial operations.

5. Versatility: The machine can handle a variety of materials, including paper, cardboard, plastic, and even certain types of fabric. This versatility makes it suitable for a wide range of applications.

How Does the Machine Work?

The operation of an Automatic Embossing Laminating Machine can be broken down into the following steps:

1. Material Feeding: The material to be embossed and laminated is fed into the machine, either manually or via an automatic feeder.

2. Embossing: The material passes through the embossing unit, where it is pressed between an engraved roller and a counter roller. The pressure and heat applied cause the material to take on the design of the engraved roller.

3. Laminating: Immediately after embossing, the material enters the laminating unit. Here, a laminating film is applied to the surface of the embossed material. Heat and pressure are again used to bond the film securely to the material.

4. Cooling and Finishing: The laminated material is then cooled to solidify the bond. Some machines have additional finishing units, such as cutting or trimming stations, to produce the final product.

Applications of the Automatic Embossing Laminating Machine

This machine is used across various industries, including:

- Packaging: Creating embossed and laminated boxes, labels, and wrappers for luxury goods.

- Publishing: Producing high-end book covers, folders, and promotional materials.

- Decorative Printing: Crafting textured and laminated prints for home décor, wallpapers, and greeting cards.

- Stationery: Manufacturing embossed and laminated business cards, invitation cards, and certificates.

Benefits of Using an Automatic Embossing Laminating Machine

1. Enhanced Aesthetic Appeal: The combination of embossing and laminating adds a premium look and feel to printed materials, making them stand out in the market.

2. Durability: Laminating not only enhances appearance but also protects materials from moisture, UV rays, and physical damage, extending the product's lifespan.

3. Efficiency: The automation of both embossing and laminating processes in a single machine reduces production time and labor costs.

4. Consistency: Automation ensures that each piece produced is of uniform quality, reducing the chances of defects and waste.

Conclusion

The Automatic Embossing Laminating Machine represents a significant advancement in the printing industry, combining two critical processes into one efficient and precise operation. By understanding how this machine works and the benefits it offers, businesses can make informed decisions to enhance their production capabilities, reduce costs, and produce high-quality, durable products that meet the demands of modern consumers.