Shaping the Future: The Crucial Role of Extrusion Equipment in Type B Structural Wall Winding Pipe Production

2023-11-14

Introduction:

In the realm of advanced engineering and construction, the production of Type B Structural Wall Winding Pipe demands precision, durability, and structural integrity. At the heart of this manufacturing process lies extrusion equipment, a technological marvel that plays a pivotal role in shaping the future of pipe production. In this blog post, we'll explore the primary function of extrusion equipment in the intricate dance of creating Type B Structural Wall Winding Pipes.

1. Understanding Type B Structural Wall Winding Pipe:

- Type B Structural Wall Winding Pipe is known for its robust structure and versatile applications in various industries, including drainage systems, underground infrastructure, and industrial pipelines.

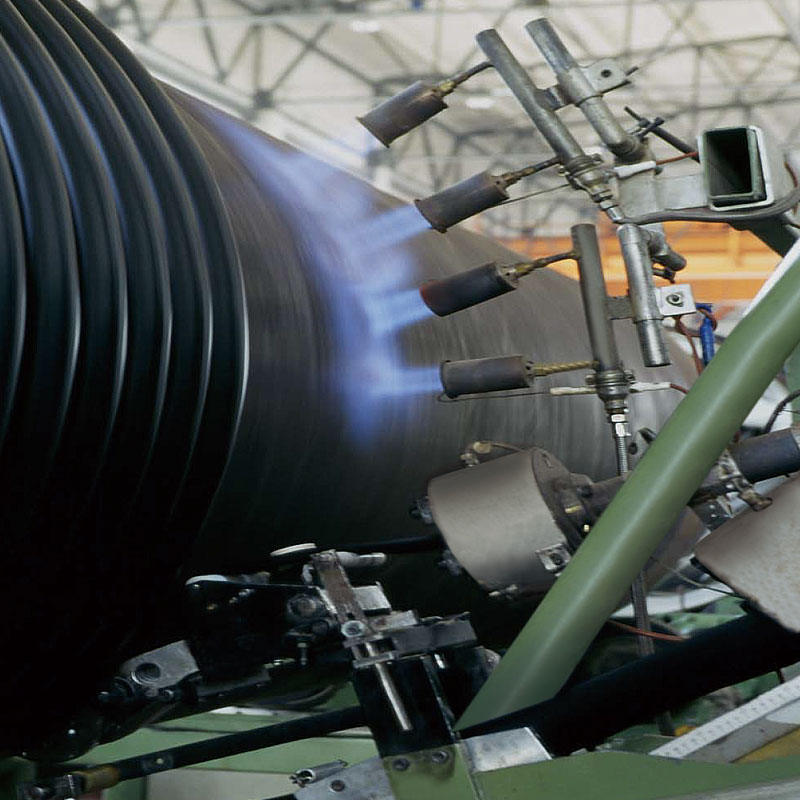

2. The Core Function of Extrusion Equipment:

- Extrusion equipment serves as the backbone of the manufacturing process for Type B Structural Wall Winding Pipe. Its primary function is to shape and form the raw materials into a seamless and structurally sound pipe through the extrusion process.

3. The Extrusion Process Unveiled:

- Extrusion involves forcing a material, typically a polymer or composite, through a die or mold of a specific shape. In the context of Type B Structural Wall Winding Pipe, the extrusion equipment precisely molds the material into the desired pipe profile.

4. Material Transformation:

- One of the key functions of extrusion equipment is to transform raw materials into a pipe with the required structural characteristics. The process imparts strength, flexibility, and durability to the material, ensuring it meets the stringent standards associated with Type B Structural Wall Winding Pipe.

5. Shaping Structural Integrity:

- Extrusion equipment is designed to impart structural integrity to the pipe during the manufacturing process. This is crucial for Type B Structural Wall Winding Pipe, as it often needs to withstand substantial loads, pressures, and environmental conditions.

6. Precision in Diameter and Thickness:

- The extrusion equipment's role extends beyond shaping the pipe; it ensures precision in diameter and thickness. This accuracy is paramount, as it directly influences the pipe's performance and compatibility with industry standards.

7. Seamless Integration of Reinforcements:

- Type B Structural Wall Winding Pipe often requires additional reinforcements for enhanced strength. Extrusion equipment facilitates the seamless integration of these reinforcements, ensuring a homogeneous structure that meets or exceeds engineering specifications.

8. Customization for Varied Applications:

- The versatility of extrusion equipment allows for customization to meet the specific requirements of different applications. Whether it's for drainage systems, industrial pipelines, or underground infrastructure, the extrusion process adapts to create pipes tailored for varied uses.

9. Efficient and Continuous Production:

- Extrusion equipment enables efficient and continuous production, allowing for the creation of Type B Structural Wall Winding Pipe in large quantities. This scalability is crucial for meeting the demands of infrastructure projects and industrial applications.

10. Technological Advancements:

- Ongoing technological advancements in extrusion equipment contribute to improved efficiency, precision, and sustainability in Type B Structural Wall Winding Pipe production. Innovations continue to shape the landscape of pipe manufacturing for the better.

Conclusion:

In the intricate dance of creating Type B Structural Wall Winding Pipe, extrusion equipment takes center stage. Its primary function of shaping and molding raw materials with precision and efficiency ensures that the resulting pipes meet the highest standards of durability and structural integrity. As technology continues to evolve, extrusion equipment remains a key player in shaping the future of pipe production, driving innovation in construction and engineering projects worldwide.