Revolutionizing Construction: Exploring the Fully Automatic Non Burning Brick Machine

2024-05-07

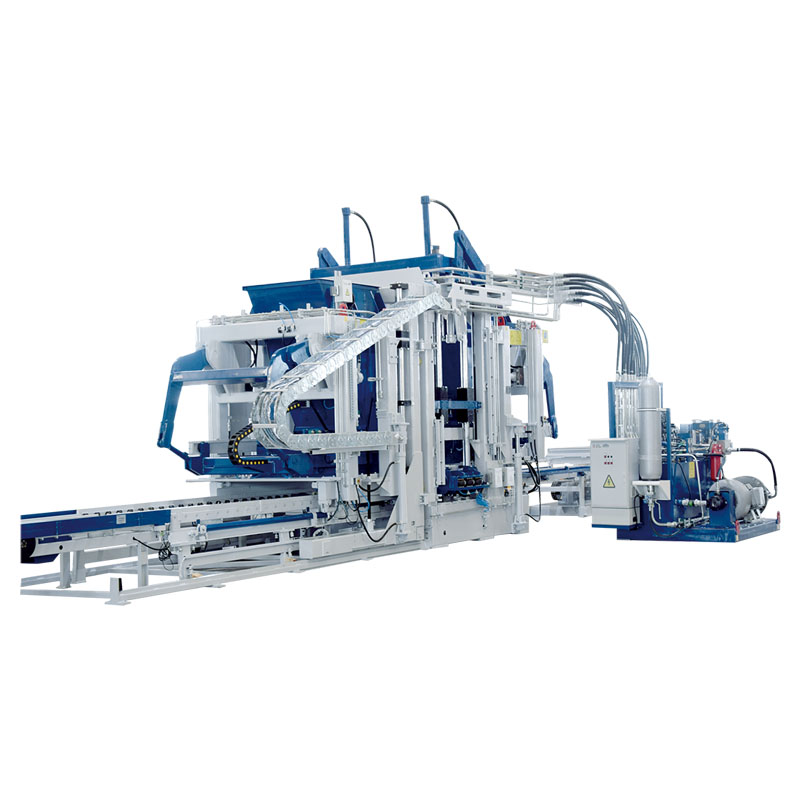

Innovations in construction technology are reshaping the way we build, offering faster, more efficient, and more sustainable alternatives to traditional methods. Among these groundbreaking advancements is the Fully Automatic Non Burning Brick Machine, a game-changer in the realm of brick-making. Let's delve into the key features and functionalities of this revolutionary machine and examine how it sets itself apart from traditional brick-making technologies.

1. Sustainable Material Usage:

One of the standout features of the Fully Automatic Non Burning Brick Machine is its utilization of sustainable materials. Unlike traditional brick-making methods, which often rely on clay and require high-temperature firing in kilns, this innovative machine produces bricks without the need for burning. Instead, it employs cutting-edge technology to compress and mold materials such as fly ash, cement, and industrial waste into durable and environmentally friendly bricks. By reducing reliance on clay and eliminating the carbon emissions associated with kiln firing, the Fully Automatic Non Burning Brick Machine offers a more sustainable alternative for construction projects.

2. Energy Efficiency:

Another key feature of the Fully Automatic Non Burning Brick Machine is its energy efficiency. Traditional brick-making processes require significant amounts of energy for clay extraction, transportation, and firing in kilns, contributing to carbon emissions and environmental degradation. In contrast, this advanced machine operates with minimal energy consumption, utilizing hydraulic pressure and automation to compress and form bricks efficiently. By reducing energy requirements and optimizing production processes, the Fully Automatic Non Burning Brick Machine helps minimize its environmental footprint and promote sustainable construction practices.

3. High Production Capacity:

The Fully Automatic Non Burning Brick Machine boasts impressive production capacity, capable of manufacturing large quantities of bricks in a relatively short period. Equipped with automated systems and precision engineering, this machine can produce bricks at a rapid pace, streamlining construction timelines and reducing project costs. Whether it's for residential, commercial, or infrastructure projects, the high production capacity of this machine ensures timely delivery of quality bricks to meet the demands of modern construction projects.

4. Versatility and Customization:

In addition to its sustainability and efficiency, the Fully Automatic Non Burning Brick Machine offers unparalleled versatility and customization options. Unlike traditional brick-making methods, which are limited by the properties of clay and the constraints of kiln firing, this machine can process a wide range of raw materials and produce bricks of various sizes, shapes, and colors. Whether it's standard red bricks for traditional buildings or specialized blocks for innovative architectural designs, the Fully Automatic Non Burning Brick Machine can fulfill diverse construction needs with ease.

5. Cost-Effectiveness:

Last but not least, the Fully Automatic Non Burning Brick Machine offers significant cost savings compared to traditional brick-making technologies. By reducing material waste, energy consumption, and labor costs, this machine provides a more cost-effective solution for brick production, enabling builders and developers to optimize project budgets and maximize returns on investment. Whether it's for large-scale construction projects or small-scale renovations, the cost-effectiveness of the Fully Automatic Non Burning Brick Machine makes it an attractive choice for builders and contractors worldwide.

In conclusion, the Fully Automatic Non Burning Brick Machine represents a paradigm shift in brick-making technology, offering sustainable, energy-efficient, high-capacity, versatile, and cost-effective solutions for modern construction projects. By harnessing the power of innovation and automation, this revolutionary machine is paving the way for a greener, more efficient, and more sustainable future in the construction industry.