Innovations and Future Prospects of Parallel Comb Idlers

2024-07-12

Introduction

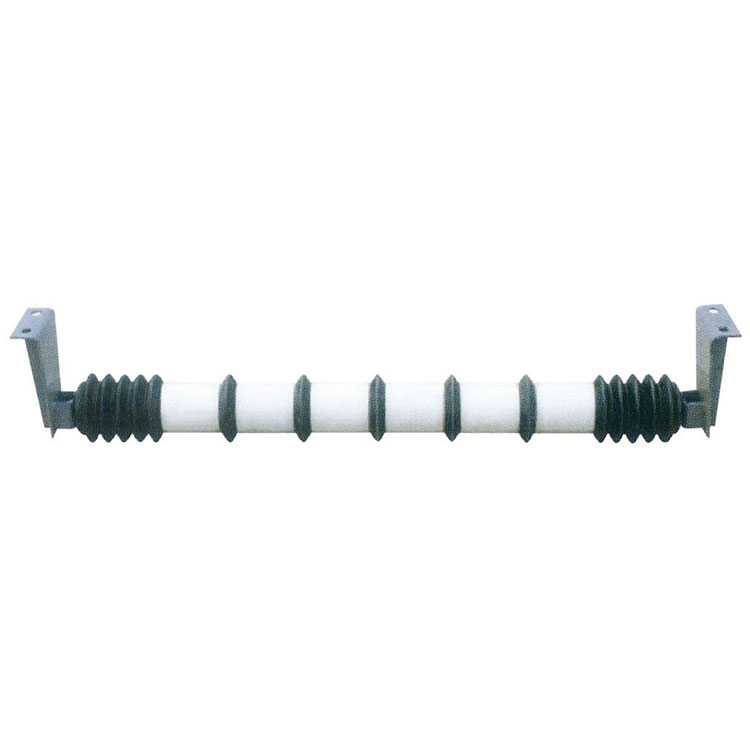

As industries evolve, so do the technologies that support them. The Parallel Comb Idler is a prime example of innovation in conveyor system components. This blog will discuss recent advancements in Parallel Comb Idler technology, their impact on industry practices, and future prospects.

Recent Advancements in Parallel Comb Idler Technology

1. Materials and Durability

- Modern Parallel Comb Idlers are constructed using high-strength, wear-resistant materials. Innovations in material science have led to idlers that can withstand harsher conditions and last longer, even in demanding environments.

2. Improved Design

- Advances in design have resulted in more efficient and effective Parallel Comb Idlers. Enhanced comb structures provide better support and alignment, while also being lighter and easier to install.

3. Smart Monitoring

- The integration of smart monitoring technologies allows for real-time data collection on the performance of Parallel Comb Idlers. Sensors can detect misalignment, wear, and other issues, enabling proactive maintenance and reducing downtime.

4. Energy Efficiency

- Newer models are designed to be more energy-efficient, reducing the overall power consumption of the conveyor system. This not only lowers operational costs but also supports sustainability goals.

Impact on Industry Practices

1. Enhanced Operational Efficiency

- The improvements in Parallel Comb Idler technology have led to more efficient conveyor systems. Enhanced support and alignment reduce disruptions, allowing for smoother and faster material transport.

2. Cost Savings

- The durability and reliability of modern Parallel Comb Idlers translate to lower maintenance and replacement costs. Additionally, the energy-efficient designs reduce power consumption, further cutting operational expenses.

3. Improved Safety Standards

- Innovations that reduce spillage and noise contribute to safer working environments. The use of smart monitoring technology allows for early detection of potential issues, preventing accidents and enhancing overall workplace safety.

4. Sustainability

- The focus on energy efficiency and the use of durable, long-lasting materials align with sustainability initiatives. Industries can reduce their environmental footprint while maintaining high operational standards.

Future Prospects of Parallel Comb Idlers

1. Integration with IoT

- The Internet of Things (IoT) is set to revolutionize how conveyor systems operate. Parallel Comb Idlers integrated with IoT capabilities will offer enhanced monitoring, predictive maintenance, and data-driven decision-making.

2. AI and Machine Learning

- The integration of artificial intelligence (AI) and machine learning will further optimize the performance of Parallel Comb Idlers. These technologies can analyze data to predict failures, optimize settings, and improve overall system efficiency.

3. Sustainable Materials

- The development of new, eco-friendly materials will make Parallel Comb Idlers even more sustainable. These materials will offer the same, if not better, performance while reducing the environmental impact.

4. Customization and Modularity

- Future idlers will likely offer greater customization and modularity. This will allow industries to tailor their conveyor systems to specific needs, enhancing flexibility and efficiency.

Conclusion

The Parallel Comb Idler is a testament to the ongoing innovation in conveyor system technology. Recent advancements have improved their performance, durability, and efficiency, making them an integral part of modern material handling systems. Looking ahead, the integration of IoT, AI, and sustainable materials promises to further enhance the capabilities and benefits of Parallel Comb Idlers. By staying at the forefront of these developments, industries can continue to optimize their operations, reduce costs, and support sustainability goals.