Exploring the Main Components of a Press Die Mold

2024-05-31

In the world of metalworking and manufacturing, press die molds play a crucial role in shaping and forming various metal components. These precision tools are designed to withstand the high pressures and temperatures required for metal forming processes. Understanding the main components of a press die mold is essential for ensuring its efficient operation and long-term durability.

The first component we'll explore is the upper die, often referred to as the punch. The punch is responsible for pressing the metal workpiece into the desired shape. It is made from a hard and wear-resistant material, such as tool steel, to ensure it can withstand the repetitive forces exerted during the forming process.

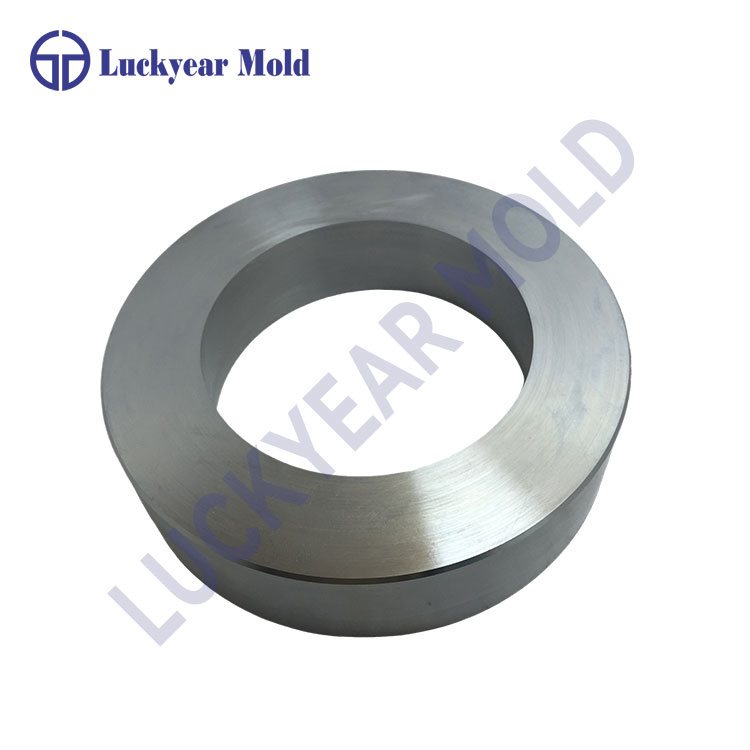

The lower die, or die block, is the counterpart to the punch. It has a cavity that matches the shape of the desired product. When the punch descends, it forces the metal workpiece into this cavity, resulting in the desired shape. The die block is also made from a durable material that can withstand the pressures and temperatures encountered during metal forming.

Another crucial component is the guide system. This system ensures that the punch and die block align properly during the forming process. It typically consists of guide pins and bushings that fit together precisely, allowing the punch to move vertically while maintaining its alignment. A properly functioning guide system is essential for achieving accurate and repeatable results.

The ejection system is also an important part of a press die mold. This system is responsible for removing the formed product from the die after each cycle. It typically consists of ejector pins or plates that are actuated by a mechanical or pneumatic system. The ejection system must be designed to ensure that the product is removed cleanly and without damage.

Finally, the mold base is the structural foundation that holds all the components of the press die mold together. It is typically made from a heavy-duty material that can withstand the rigors of the metal forming process. The mold base also provides the necessary stability and rigidity to ensure accurate and consistent results.

In conclusion, the main components of a press die mold include the upper die (punch), lower die (die block), guide system, ejection system, and mold base. Each of these components plays a crucial role in ensuring the efficient and reliable operation of the mold. Understanding the function and design of these components is essential for anyone involved in the metalworking and manufacturing industry.