Exploring Aluminum Sheet Stamping: A Primer on Metal Forming

2024-04-17

In the vast world of manufacturing, precision and efficiency are paramount. When it comes to shaping metals into intricate designs and functional components, various processes come into play. One such method that stands out for its versatility and effectiveness is aluminum sheet stamping. In this blog post, we'll delve into what aluminum sheet stamping is and how it sets itself apart from other metal forming processes.

Understanding Aluminum Sheet Stamping

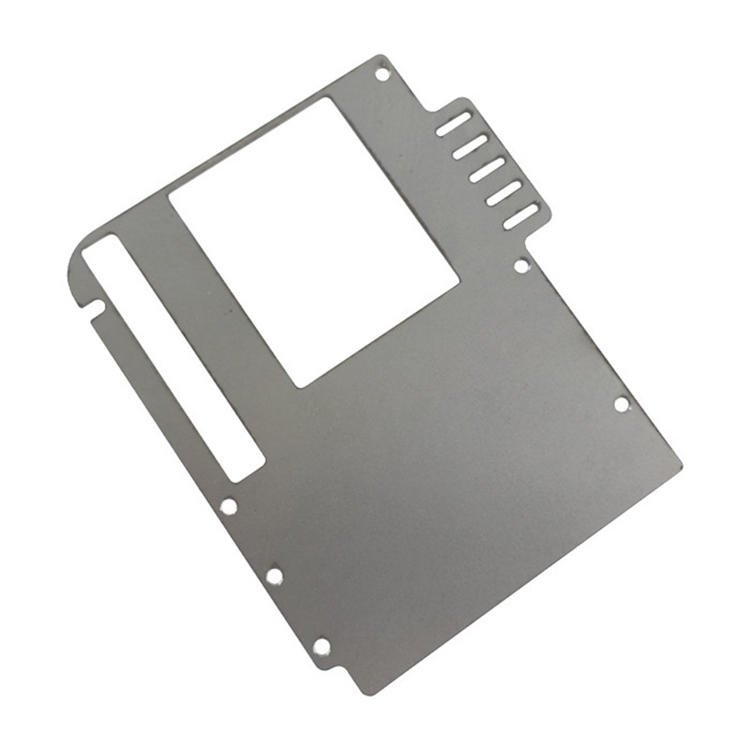

Aluminum sheet stamping is a metal forming process that involves shaping flat sheets of aluminum into desired forms using specialized tools and machinery. The process typically begins with a flat sheet of aluminum, which is placed onto a die and subjected to high pressure from a punch. This pressure forces the aluminum to conform to the shape of the die, resulting in a stamped part with the desired geometry.

How It Differs from Other Metal Forming Processes

1. Versatility:

Aluminum sheet stamping offers remarkable versatility, allowing manufacturers to create a wide range of complex shapes and designs with precision. Unlike some other metal forming processes that may be limited in their capabilities, aluminum sheet stamping can handle intricate patterns and tight tolerances with ease.

2. Cost-Effectiveness:

Compared to processes like CNC machining or casting, aluminum sheet stamping is often more cost-effective, especially for high-volume production runs. The ability to rapidly stamp out parts from flat sheets of aluminum reduces material waste and labor costs, making it an attractive option for manufacturers seeking efficiency without sacrificing quality.

3. Speed and Efficiency:

Aluminum sheet stamping can be a highly efficient process, particularly when automated systems are employed. With advancements in stamping technology, manufacturers can produce parts at a rapid pace, meeting tight production deadlines without compromising on quality. This speed and efficiency make aluminum sheet stamping a preferred choice for industries where time-to-market is critical.

4. Material Considerations:

Aluminum's unique properties make it well-suited for sheet stamping applications. It is lightweight, corrosion-resistant, and possesses excellent formability, allowing it to be easily shaped without compromising its structural integrity. Additionally, aluminum's high strength-to-weight ratio makes it ideal for applications where strength and durability are essential.

5. Surface Finish:

Aluminum sheet stamping can produce parts with a high-quality surface finish, eliminating the need for additional finishing processes in many cases. This can result in cost savings and streamlined production workflows, as parts can go directly from the stamping press to assembly or installation.

Conclusion

In summary, aluminum sheet stamping is a highly versatile and efficient metal forming process that offers numerous advantages over other methods. From its ability to create complex shapes with precision to its cost-effectiveness and speed, aluminum sheet stamping has become a cornerstone of modern manufacturing across various industries. As technology continues to evolve, we can expect to see further advancements in aluminum sheet stamping techniques, enabling even greater innovation and efficiency in the production of metal components.