Enlightening Choices: The Environmental Edge of LED T5 Plastic Tube Housing

2023-12-08

Introduction:

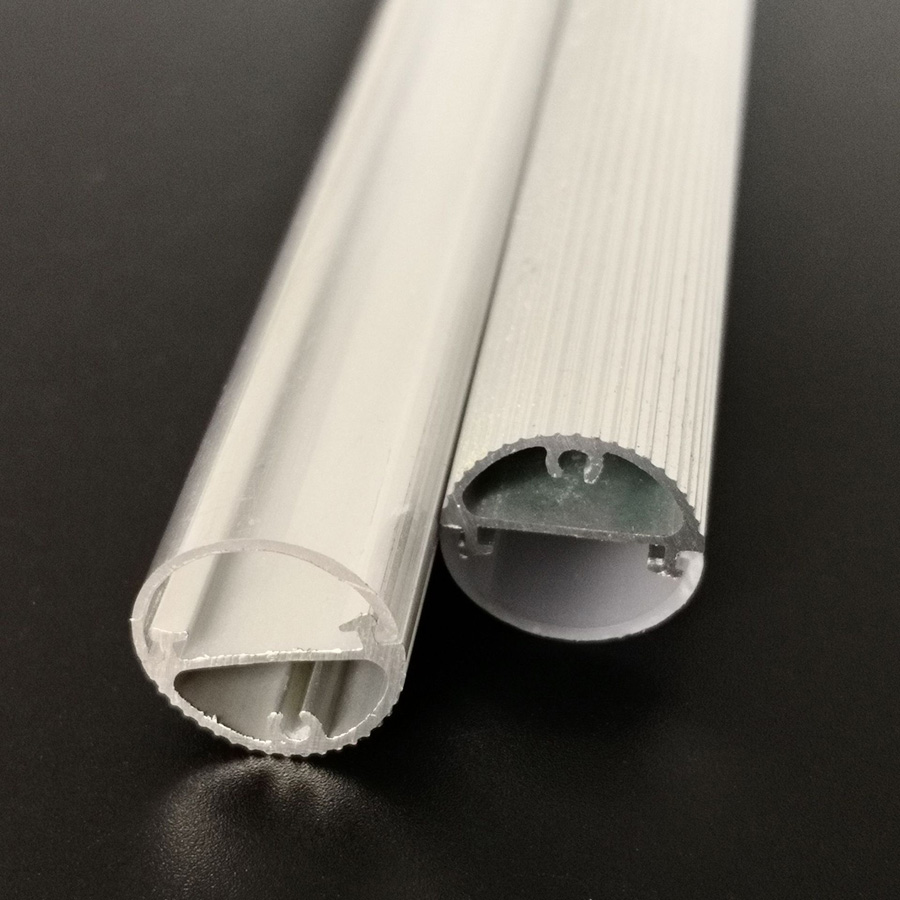

In the dynamic world of lighting solutions, the choice of materials for housing plays a crucial role in determining the adaptability and performance of LED tubes. The rise of LED T5 plastic tube housing has been notable, raising questions about its suitability in comparison to other housing materials. In this blog, we explore specific environmental conditions and applications where LED T5 plastic tube housing stands out, showcasing its unique advantages over alternative materials.

1. Moisture-Prone Environments:

LED T5 plastic tube housing, often made from materials like polycarbonate or acrylic, exhibits excellent resistance to moisture. This makes it particularly suitable for environments with high humidity levels, such as bathrooms, kitchens, or outdoor installations, where traditional materials like glass may be more susceptible to corrosion.

2. Corrosive Atmospheres:

In industrial settings where corrosive gases or chemicals are present, the corrosion-resistant properties of plastic housing can provide a protective barrier for the internal components of LED T5 tubes. This makes plastic housing a preferred choice over materials like metal, which may succumb to corrosion over time.

3. Lightweight Construction for Easy Installation:

LED T5 plastic tube housing is inherently lightweight, making it easier to handle and install. This is advantageous in scenarios where the installation process involves mounting the tubes in challenging or elevated locations. The reduced weight simplifies installation without compromising durability.

4. Impact Resistance in High-Traffic Areas:

Plastic materials, especially polycarbonate, offer superior impact resistance compared to glass or other materials. In high-traffic areas where accidental impacts or vibrations are common, LED T5 plastic tube housing can withstand such occurrences without the risk of breakage or damage.

5. Versatility in Architectural Integration:

The malleability of plastic allows for diverse design possibilities, making LED T5 plastic tubes suitable for various architectural and interior design applications. The flexibility in design enables seamless integration into different environments, offering aesthetic versatility beyond the constraints of rigid materials.

6. Outdoor Lighting:

LED T5 plastic tube housing is well-suited for outdoor lighting applications. Its resistance to UV radiation ensures that the housing retains its integrity and does not degrade over time when exposed to sunlight. This makes plastic housing a reliable choice for landscape lighting, parking lots, and other outdoor settings.

7. Reduced Energy Consumption:

The lightweight nature of LED T5 plastic tube housing contributes to energy efficiency during transportation and installation. The reduced weight means lower transportation costs and less energy required for installation, aligning with sustainability goals and reducing the overall environmental impact.

8. Insulation and Safety:

Plastic housing provides an additional layer of insulation, enhancing safety in certain environments. In applications where electrical insulation is crucial, plastic housing can be advantageous over materials that conduct electricity.

Conclusion:

While LED T5 plastic tube housing may not be a one-size-fits-all solution, its unique set of properties makes it particularly well-suited for specific environmental conditions and applications. The resistance to moisture, impact, and corrosion, coupled with its lightweight and versatile design, positions LED T5 plastic tube housing as a reliable and environmentally conscious choice in diverse lighting scenarios. As the lighting industry continues to evolve, the versatility and adaptability of plastic housing materials contribute to a brighter and more sustainable future.