Color-Coated Galvanized Steel Coils: Unveiling the Versatility Across Industries

2023-11-27

Introduction:

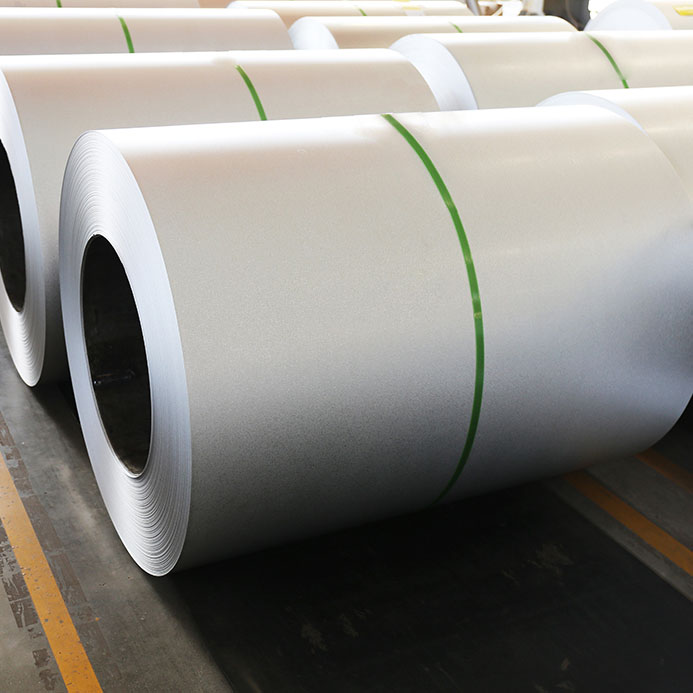

In the world of construction and manufacturing, materials that marry durability with aesthetics are a sought-after commodity. Color-coated galvanized steel coils have emerged as a versatile solution, finding applications across diverse industries. In this blog, we'll explore the industries and applications that typically utilize these coils and understand why they are the preferred choice in these realms.

1. Construction and Architecture:

Color-coated galvanized steel coils have become the darling of architects and builders in the construction industry. The blend of corrosion resistance from galvanization and the customizable color coating allows for the creation of structures that not only stand the test of time but also exude visual appeal. From roofing and cladding to facades and structural elements, these coils provide a perfect marriage of form and function.

2. Automotive Manufacturing:

The automotive industry demands materials that can withstand the rigors of the road while meeting stringent aesthetic standards. Color-coated galvanized steel finds its place in car bodies, interior components, and undercarriage elements. The robust protection against corrosion ensures the longevity of automotive parts, while the color coating allows for brand-specific customization and design flexibility.

3. Appliance Manufacturing:

Household appliances, such as refrigerators, washing machines, and ovens, benefit from the corrosion resistance and visual appeal of color-coated galvanized steel. The coils provide a protective layer that prevents rusting, extending the lifespan of appliances. Additionally, manufacturers can offer a variety of colors to match diverse consumer preferences.

4. Signage and Outdoor Displays:

The outdoor signage industry relies on materials that can withstand exposure to the elements. Color-coated galvanized steel, with its weather-resistant topcoat, serves as an ideal choice for signage and outdoor displays. The customizable color options allow for eye-catching and brand-consistent displays that can endure outdoor conditions.

5. Infrastructure and Transportation:

Bridges, railings, and transportation infrastructure benefit from the durability and corrosion resistance of color-coated galvanized steel. The ability to customize the color coating facilitates the integration of these materials into the overall aesthetic design of transportation hubs and infrastructure projects.

6. Electrical Enclosures and Cabinets:

In the electrical and electronics industry, where protection against corrosion is paramount, color-coated galvanized steel finds application in enclosures and cabinets. The coils provide a reliable shield against environmental factors, ensuring the safety and longevity of electrical components.

Why Color-Coated Galvanized Steel Coils?

1. Corrosion Resistance:

The galvanization process provides a robust defense against corrosion, making these coils ideal for applications in challenging environments.

2. Aesthetic Versatility:

The customizable color coating allows for a wide range of aesthetic possibilities, catering to diverse design preferences in various industries.

3. Longevity and Durability:

The combination of galvanization and color coating ensures a long-lasting and durable material that can withstand the demands of different applications.

4. Cost-Effectiveness:

The total cost of ownership is often lower due to the extended lifespan and minimal maintenance requirements, making them a cost-effective choice over time.

In conclusion, color-coated galvanized steel coils have found favor in industries that prioritize both functionality and visual appeal. As technology continues to advance, these coils are likely to evolve, offering even more innovative solutions to meet the diverse needs of modern construction and manufacturing.