Coating Thickness and Its Impact on Steel Coil Performance

2024-04-25

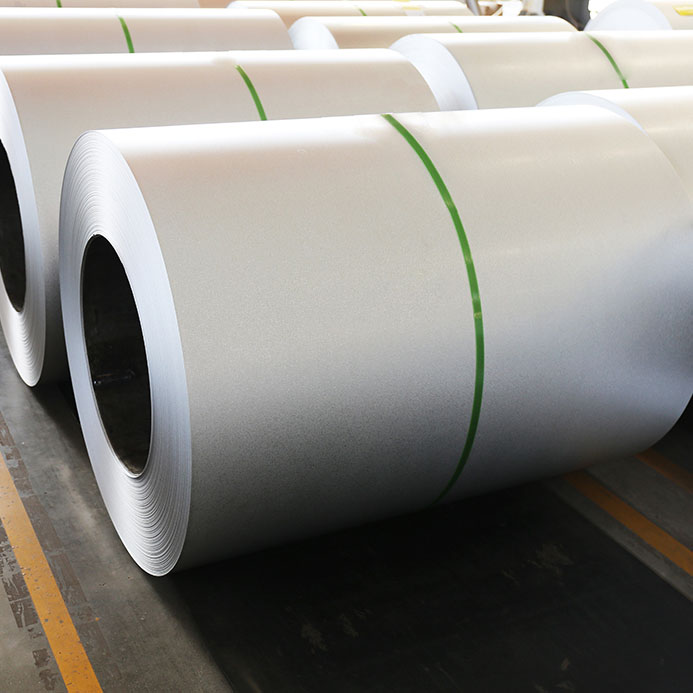

In the world of industrial manufacturing, steel coils play a crucial role, often finding their way into various applications such as roofing, automotive parts, and even appliances. One crucial aspect that determines the performance of these steel coils is the thickness of the coating applied to them. Let's delve into how coating thickness affects the performance of steel coils.

1. Corrosion Resistance

The primary function of coatings on steel coils is to provide a protective barrier against corrosion. When the coating is too thin, it may not be able to effectively resist moisture, oxygen, and other corrosive agents. This can lead to premature rusting and degradation of the steel, reducing its lifespan and performance. On the other hand, a thicker coating offers better corrosion resistance, ensuring the steel coil remains intact for longer.

2. Appearance and Finish

The thickness of the coating also plays a role in determining the overall appearance and finish of the steel coil. A thin coating may not provide a uniform or smooth finish, resulting in a less appealing aesthetic. A thicker coating, however, can create a smoother and more consistent surface, enhancing the visual appeal of the steel coil.

3. Mechanical Properties

The thickness of the coating can also affect the mechanical properties of the steel coil. A thicker coating may add additional weight to the coil, which could be a concern in applications where weight is a critical factor, such as in the automotive industry. Additionally, the coating material itself may have different mechanical properties that could alter the overall performance of the steel coil.

4. Durability

Durability is another crucial aspect that is influenced by coating thickness. A thicker coating typically offers better durability, resisting scratches, dents, and other forms of physical damage. This enhanced durability ensures that the steel coil can withstand harsher environments and longer use without significant degradation.

5. Cost Considerations

It's worth noting that thicker coatings do not always equate to better performance. In fact, using unnecessarily thick coatings can lead to increased material costs without providing any significant benefits. Therefore, it's important to strike a balance between coating thickness and performance requirements to ensure cost-effective solutions.

In conclusion, the thickness of the coating applied to steel coils has a significant impact on its performance. It affects corrosion resistance, appearance, mechanical properties, durability, and even cost. Understanding these relationships is crucial for manufacturers to make informed decisions when selecting coatings for their steel coils, ensuring optimal performance and cost-effectiveness.